Supply chain boosted by a dynamic, demanding and competitive market

The unfavorable economic context of these last years, as well as the evolution of our society’s consumption patterns (local offers, customized offers, at the right price), constrain companies to transform themselves to be able to answer higher customers expectations and face the competitive pressure.

In this context, manufacturers are forced to rethink their supply chain’s structuring to gain agility, robustness and performance. These transformations must respond to market challenges and develop a strong competitive advantage throughout the value chain.

Whether they are strategic or organizational, the transformations must also include a digital component to modernize, gain in information reliability and operational performance. These are outstanding advantages in the market.

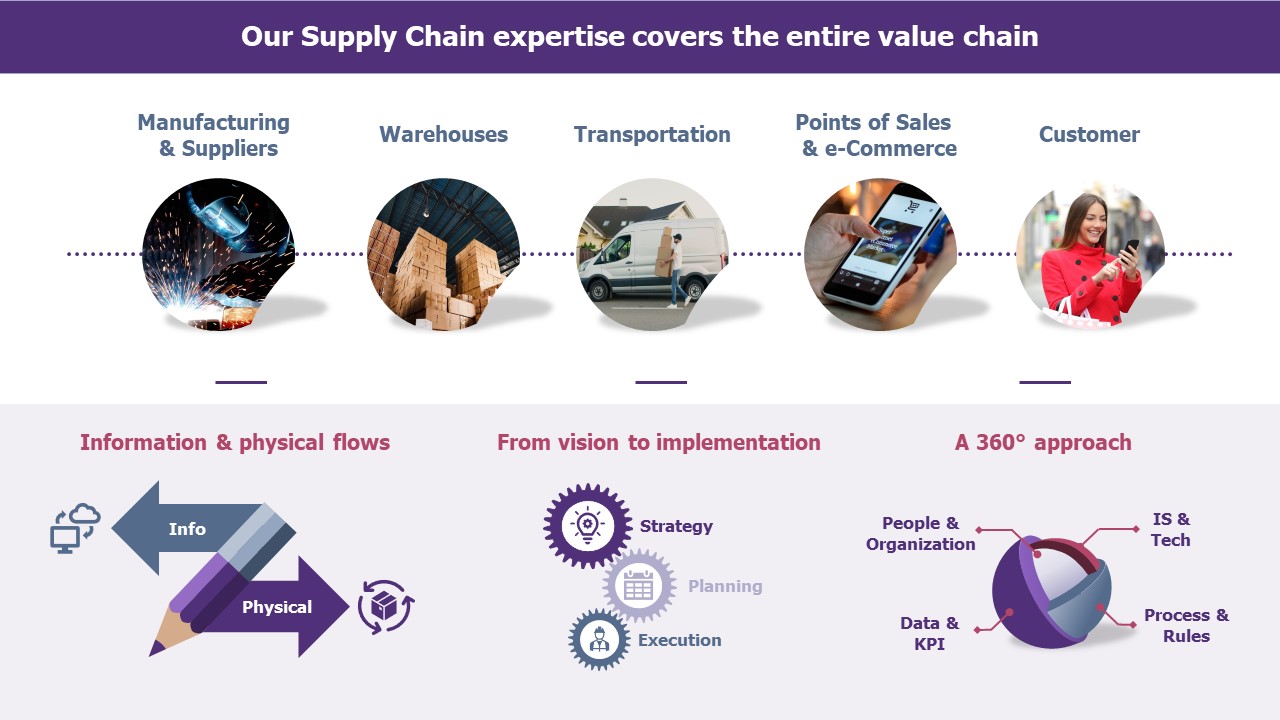

We support you along the supply chain, from the product creation to the end-customer

Our expertise covers supply chain in its whole: from product sourcing to procurement, from production to warehouse management, from transportation to the organization of customer outlets.

In all of your transformations, we strive to integrate change management and consider the environmental emergency to work together for sustainable transformations.

The combination of our business and technological know-how allows us to act on the following topics:

We support you to (re)define your paradigm:

- Redefinition of the target operating model: from end-to-end diagnostics to transformation planning and organization design, Wavestone’s teams will guide you toward your target operating model to meet market challenges and the defined customer promise.

- Logistics network optimization: for any company, defining and optimizing its distribution network is a strategic challenge. It’s a question not only of positioning your offers and services in a given market, but also of assessing the impact of each potential strategy in terms of costs, financial assets (inventory), and service levels. Before becoming operational realities, we draw up a logistics master plan that integrates the project’s structuring and prospective elements and defines the target organization and roadmap to get there.

- Supply chain security: the economic and health crisis has revealed the fragility of supply chains and their sensitivity to risks (health, geopolitical, economic, social, technical, environmental). Faced with this situation, we have developed a proven methodology designed to cover you against these risks, which could once again turn your business upside down.

We support our customers in defining and implementing their planning strategy, enabling them to maximize service levels while optimizing costs.

We guide them in the design of target processes and organizations, and in the implementation of tools in the following areas:

- Product Offer Management

- Demand Planning

- Distribution Planning

- DDMRP

- Production Planning

- Procurement Planning and Supplier Collaboration

- S&OP / IBP

We have developed expertise in the best practices of each sector and in the various tools available on the market (APS, EPM toolbox, digital twins, control tower, etc.).

Our ambition is to bring you manufacturing and logistics expertise combined with know-how in Purchasing excellence:

- Overhaul of the purchasing operational model: creation of supply cells, redefinition of roles & responsibilities, deployment of regional processes or training, and implementation of a solution adapted to the customer’s strategy…

- Industrial Supply Chain: We support our customers in their industrial supply chain tools transformation, enabling them to gain agility, responsiveness, and efficiency.

We guide our customers from the definition of target processes, the selection and design of solutions, right through to the implementation and ramp-up of high-impact projects:

– Industrial master plan, Make or Buy strategy, transformation or creation of industrial sites.

– Diagnosis and optimization of processes (flow management, line-side logistics, procurement, inventory management, production, order to delivery, lean approach, …)

– Support for the design and implementation of MES (Manufacturing Execution System) tools to meet the challenges of efficiency, visibility, quality, traceability, etc.

– Support for the design and implementation of scheduling tools adapted to specific business requirements.

– Industrial logistics automation: recommendations and implementation of innovative solutions (AGVs, IoT, mobility, exoskeletons, etc.) to improve productivity, capacity, speed, quality, and working conditions.

To meet the logistics and distribution requirements, our expertise focuses on three areas:

- Logistics: to identify areas for improvement and design an optimized operating model, we offer to diagnose warehouse processes and costs.

We help our customers to think about outsourcing and, if necessary, to select the 3PL best suited to their activity by conducting a call for tenders.

- Intralogistics: mechanized warehousing is a big lever for reducing the drudgery of tasks, improving performance, and achieving expected service levels. We’ll help you choose an innovative solution that’s tailored to your business and your constraints. We support you from start to finish:

Solution design, equipment manufacturer tender, simulations, contracting, implementation follow-up, acceptance & testing.

- Distribution/transport: Transport operations are a key factor in the performance of your supply chain. We can help you design and optimize your distribution networks, from Full Truck Load to Last Mile. We can also manage the transport tender process.

There can be no high-performance value chain without the support of an information system and, more broadly, of appropriate technological tools.

The challenge is to reduce the gap between needs and solutions by correctly understanding business imperatives and IS constraints, while taking advantage of the benefits of supply chain digitization.

Thanks to our dual skills in business and IS (WMS, OMS, TMS, APS, WCS, Control Tower, etc.), we support our customers in :

- Definition of the Supply Chain IS master plan and its consistency with the overall IS master plan.

- IS scoping, needs analysis and solution selection assistance, right through to contractualisation with publishers x integrators.

- Secure implementation: project management, acceptance, changeover, data recovery and migration, go-live, HyperCare-type support.

- Business x Tools x Organization x Culture impact analysis, definition and implementation of the necessary change management measures.

An ecosystem at your disposal

Technological partners

While remaining independant, we have developed expertise in partner solutions.

Academic partners

We maintain a close relationship with the best schools to transmit our knowledge.

Partners in reflection

To maintain our level of expertise and innovation, we share our thoughts with supply chain experts.