As demand shifts to emerging countries and competition and regulations get tougher, industrial companies have to react. In this context, product and process development activities have to become global, more efficient and bring more value. Efficient collaboration, data and complexity management are key enablers in achieving this challenge. PLM (Product Lifecycle Management) helps companies to face these new challenges.

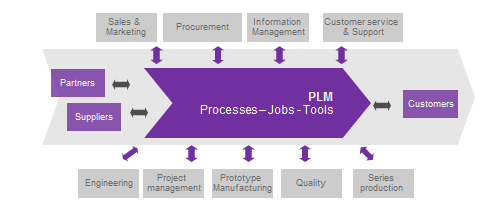

The PLM approach consists in capitalizing all information regarding an industrial product. PLM is the set of processes, competencies and tools that enable a company to innovate as well as manage its products and service offerings in an optimal manner. It covers the entire life cycle, from the initial concept to removal/recycling in a collaborative environment including every department in the company involved and external partners (clients, subcontractors, suppliers, etc).

In addition, it allows the different departments of the company, from production to the sales, to share knowledge across the different stages of a product life cycle (design, manufacture, storage, transportation, sales, after-sales service, recycling).

Costs, quality, lead time: PLM contributes to the competitiveness of a company

The benefits of the PLM approach can be analyzed according to 3 different axes:

- Quality: the PLM approach will reduce non-conformity and warranty costs, and minimize the risk of error due to multiple data entry;

- Lead time: the PLM will reduce rework activities and changes thanks to better data consistency. Moreover, it will enhance re-use through planned use of building blocks ready for integration and tasks follow-up and monitoring;

- Costs: the approach will optimize the processes (modeled, validated and shared), reduce data ‘research and management’ activities, minimize rework costs (purchasing, manufacturing and transportation) and eliminate late delivery penalties.

Several areas will be covered by PLM to meet the companycompany strategy

A group of companies ranging from railway to automotive, ship building, military, aerospace and energy have defined the areas that will be covered by a PLM project in order to meet the companycompany strategy: For each of these areas, some best practices have been identified:

- Configuration Management: One single configuration management process to increase governance of end-to-end operational performance across business and sites. All design offices working on the same “product” at the same time;

- System Engineering: generation of physical architecture from functional requirements:

- Design is focused on client requirements instead of existing technical solutions, innovation is facilitated;

- Maintenance and Service are included in design phase to increase total product and service value;

- Product design is managed at the right granularity level to improve re-use and minimize instantiation recurring costs on projects (platforming/product assets management).

- Collaboration: share databases under conditions of confidentiality and security control, internally and with external actors (partners, suppliers, clients …):

- Design is shared between several design offices, in Europe, America, Asia, etc.;

- Industrialization transfers between sites are facilitated;

- Communication with externals is efficient through the extended companycompany.

- Knowledge Acquisition & Management: share product knowledge across company and manager feedbacks from products in operation in order to improve product value, optimize maintenance, propose new services and new business models

In most cases, the PLM approach will be managed as part of the company strategy to guarantee its success

The most challenging part of a PLM project is the ability to converge to a sustainable and robust PLM target. To get benefits, each company must clearly define the objectives of the PLM project, and align key stakeholders to the vision.

Depending on the company, PLM may be part of the eCompany strategy, especially when

- a major event is causing an overall review of the organization;

- a gap is observed compared to the competition or the market

- the company expands into new fields requiring questioning its means of development, production and support.

In some situations, the PLM should be part of the company strategy but is operationally declined as a « simple » tool. In those cases, the impacts are not analyzed and largely underestimated: it represents an important risk of major failure with loss of time and money.

The first step (“Assess & scope”) is a key success factor of a PLM project. During this phase, the company vision, objectives and challenges are clearly assessed. The PLM project will be aligned to those objectives at this early stage in the process. During the “Design” phase, the current context and its evolution to achieve the objectives are analyzed in detail. Then, the requirements are analyzed and prioritized with a middle and long term plan. Finally, the impact analysis (on the processes and the related data) and the change plan are performed.The success of a PLM project goes through several stages and is measured by the level of impact in the company.

The “Build” and “Roll-out” phases consist of the operational implementation of the first phases:

During these steps, the specifications and requests for proposals are defined and the roll-out takes place.

The PLM approach is the next major challenge for the engineering-intensive industries

At the heart of the Digital Strategy of a company, PLM is still a major challenge for the industry while offering even more potential today than ever before. From marketing to engineering, production and operational support, PLM is the strategic engine for authoring, sharing and managing information and processes across the company ecosystem. It should provide the unique consistent and reliable resource of product and process definition for all activities in a company. PLM is not just a software and network issue, it is mainly a strategic matter and has a strong cultural and organization change impact. After all PLM project success and objectives achievement is mainly a human challenge.